Moving Forward

Tucker Industries moving forward with new ideas and new technology to produce parts made more effectively.

Expanding facilities and equipment to position Tucker for operating and manufacturing into the next decade.

Quality

Tucker Industries is certified IATF 16949 and ISO 14001. Utilizing our in-house Superior Tool and Die Company, for new work, maintenance and engineering changes, helps to maintain better Quality parts through better Tooling.

Experience

For exceptional experience in the art of manufacturing, make Tucker your choice. We realize production schedules change, Tucker can change it’s schedule to accommodate yours, and expedite delivery. Eighty years of manufacturing and tooling experience , third generation, IATF 16949 and ISO 14001 Certified, Veteran owned Company.

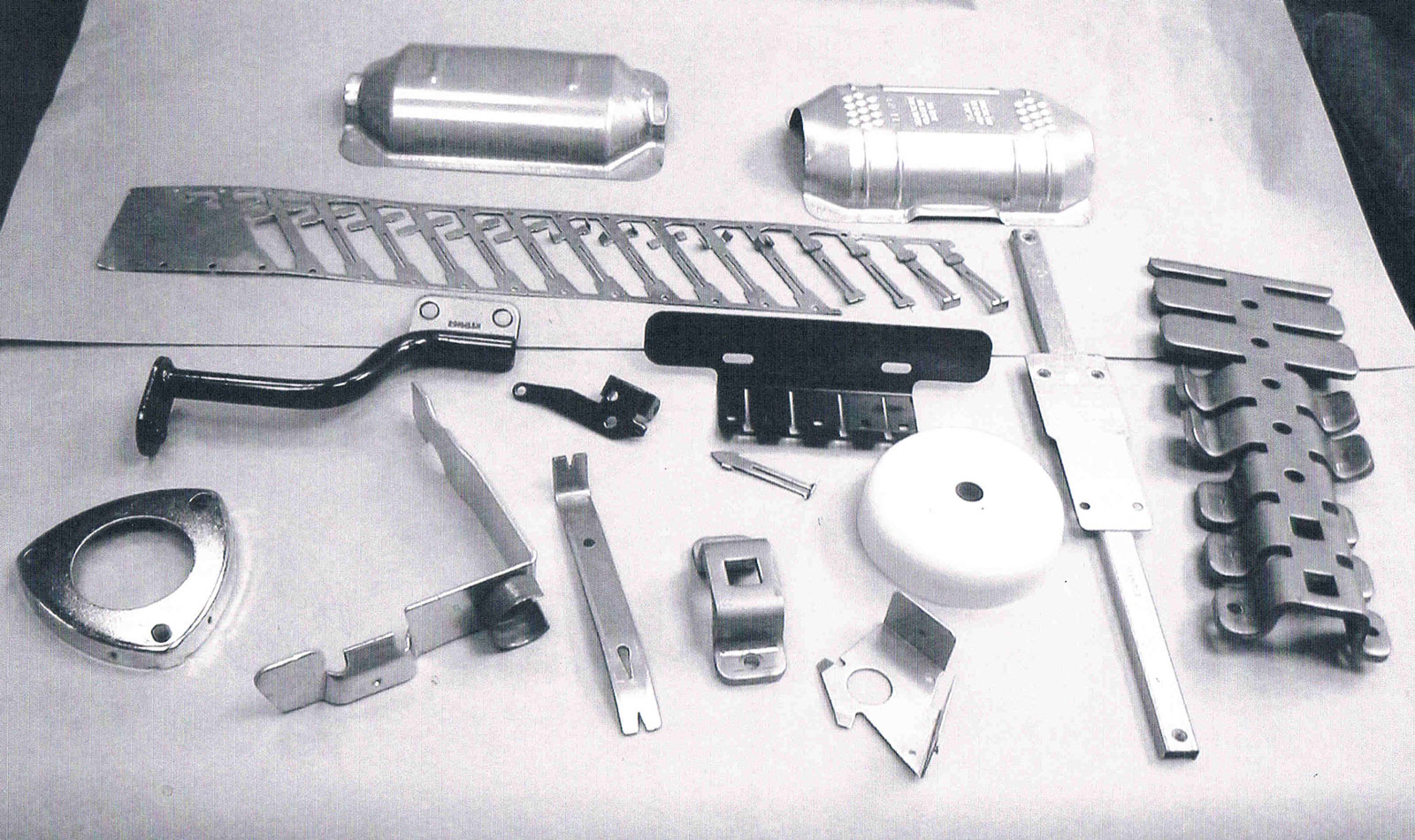

Metal Stampings

Design and build of small, medium and large stampings, parts made from steel, aluminum, stainless, using progressive, compound, tandem and secondary operation dies, to produce parts of all material, shape and size. In-die tapping and assembly of parts can be incorporated in “Tucker Tools”, eliminating secondary operations and reducing production charges. The accuracy built into the tool produces consistent quality parts.

Value Added Services

Parts can be made in one operation, what’s done to the part thereafter, becomes value added, such as heat-treating, plating, deburring, spot welding, riveting, coining, tapping, polishing, plating, ecoat, powder coat, assembly, and other miscellaneous work. Tucker also does kitting, bundling and customization. From Tuckers’ extensive tooling and roll forming capability, all sizes and shapes of lighting fixtures are produced to customer specification. Sizes vary from 2’ to 8’ long by 2’ wide parts. Tucker works with prepainted as well as unpainted material.

Robotic Welding

Robotic Welding, is welding by accurately fixturing a part or parts prior to welding. In some cases several parts may be combined to join together by welding and producing one assembly. The Tucker secret of producing high quality robotically welded parts is the accuracy level of the holding fixtures. Our robot weld fixtures are consistent in detail and are frequently maintained and upgraded in order to produce quality parts without interruption. Checking and test fixtures are nearby to insure parts are made to print, fit and function. Tucker Tool and Diemakers are used throughout the plant to insure the quality level of tooling, fixtures and production.